Inqubo yokukhiqiza yokubumba umjovo isishintshe ngokuphelele ukukhiqizwa kwemikhiqizo ehlukahlukene ezimbonini ezahlukene.

Sengeza isigaba esisha sokubumba umjovo wePlastiki, inqubo yokukhiqiza eguqule ukukhiqizwa kwemikhiqizo ehlukahlukene ezimbonini ezahlukahlukene. Kusukela ezimbonini zezimoto nezokwelapha kuye kwezikagesi nezimpahla zabathengi, ukubumba umjovo sekuyindlela edumile yokukhiqiza imikhiqizo yekhwalithi ephezulu nengabizi ukuxazulula izinkinga zamakhasimende.

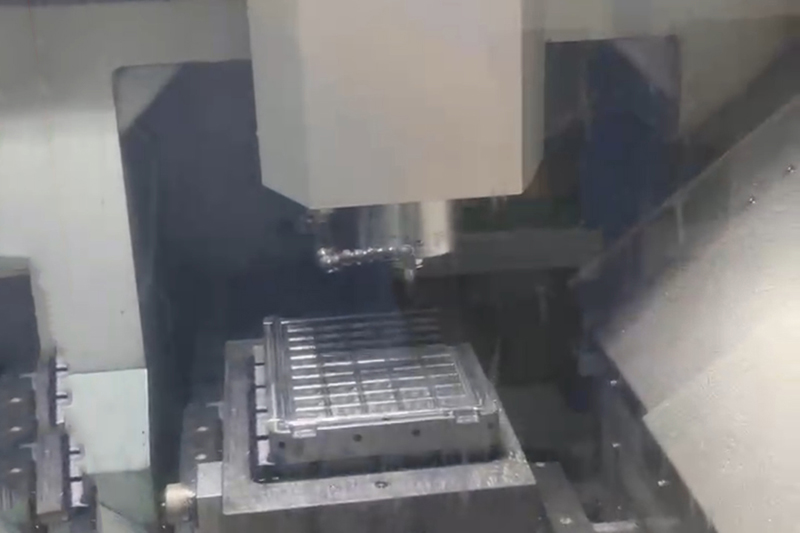

Ukubumba umjovo kuhilela ukuncibilikisa i-polymer material, ngokuvamile ngendlela yezinhlayiya, ezibe sezijovelwa emgodini wokukhunta. Impahla encibilikisiwe ithatha isimo sesikhunta, futhi ngemva kokupholisa nokuqiniswa, umkhiqizo ophelile uyaphuma esikhunjeni. Inqubo ivumela ukukhiqizwa ngobuningi bezingxenye ezifanayo ngokunemba okuphezulu nokusebenza kahle.

Ubuchwepheshe bokubumba umjovo benze inqubekelaphambili ethile. Enye intuthuko enkulu ukusetshenziswa kokuphrinta kwe-3D ekubunjweni komjovo. Lobu buchwepheshe obusha buvumela ukwakhiwa kwemiklamo yesikhunta eyinkimbinkimbi futhi eyenziwe ngokwezifiso, ngaleyo ndlela kuthuthukiswe ikhwalithi yomkhiqizo futhi kuncishiswe isikhathi sokukhiqiza. Ngaphezu kwalokho, isikhunta esiphrintiwe se-3D sibiza kakhulu uma siqhathaniswa nezibunjwa zendabuko, okwenza kube yisinqumo esithandwayo kubakhiqizi.

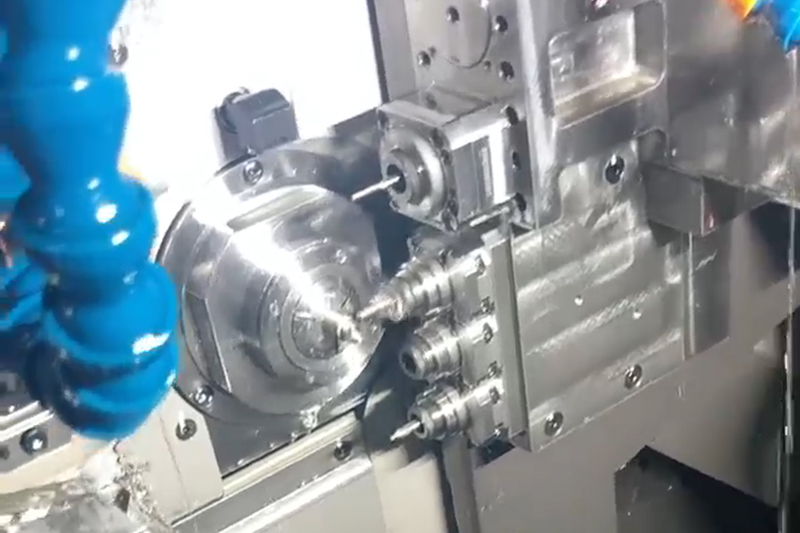

I-Automation iphinde yashintsha imboni yokubumba umjovo. Ngokuhlanganisa amarobhothi kanye nobuhlakani bokwenziwa, abakhiqizi manje bangakwazi ukwenza ngokuzenzakalelayo zonke izigaba zenqubo yokubumba umjovo, kusukela ekuphatheni impahla kuya ekususweni nasekuhlolweni kwengxenye. Lokhu akukhulisi ukukhiqiza kuphela, kodwa futhi kuqinisekisa ukulawulwa kwekhwalithi kuwo wonke umugqa wokukhiqiza.

Imboni eyodwa ezuza kakhulu ekubumbeni umjovo imboni yezimoto, yezokwelapha, yezogesi kanye nezinye. Izingxenye ezibunjwe ngomjovo zisetshenziswa kakhulu ezimotweni ngenxa yokuqina kwazo, ukunemba kanye nokusebenza kahle kwezindleko. Kusukela ezingxenyeni zangaphakathi ezifana namadeshibhodi nezibambo zeminyango kuya ezintweni zangaphandle ezifana nobhampa nama-grille, ukubumba komjovo kuguqule indlela okwenziwa ngayo izimoto. Ngaphezu kwalokho, ukuthuthuka kwezinto ezinjengama-lightweight composite kwenze izingxenye ezibunjwe ngomjovo zaduma kakhulu njengoba abakhiqizi bezimoto belwela ukunciphisa isisindo semoto.

Ikhaya

Ikhaya