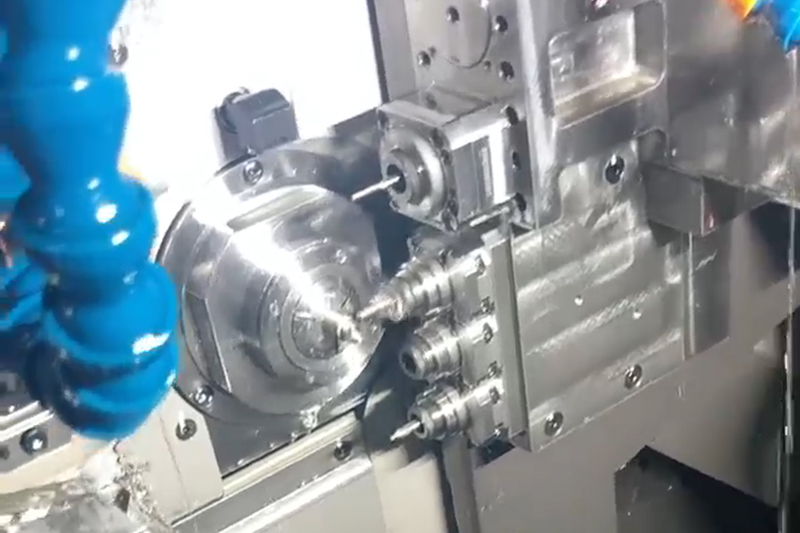

New five-axis linkage core moving machine

New equipment processing products to ensure accuracy and efficiency

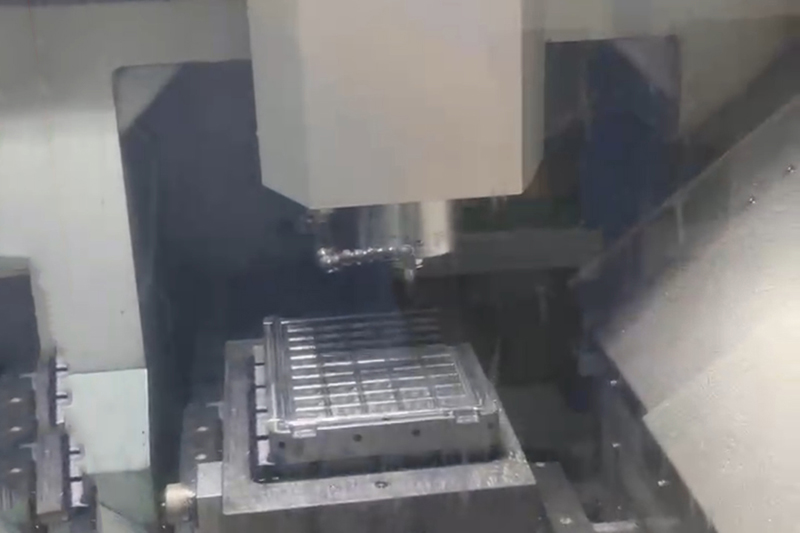

CNC vertical machining centers (VMCS) are still a staple of machine shops. These milling machines have vertically oriented spindles that allow access to workpieces mounted on the workbench from above and typically perform 2.5-axis or 3-axis machining operations. They are less costly than horizontal machining centers (HMCS), which makes them attractive for small machining shops and large machining operations. In addition, the performance of these machines has been improving over the years, taking advantage of technologies such as high-speed spindles and advanced CNC capabilities, including dialogue control programming. In addition, auxiliary equipment is provided to increase the flexibility and functionality of these machines, including spindle governors, corner heads, tool and part probes, quick change of workpiece fixture devices and rotary dividers for four - or five-axis machining work.

Almost any workshop can automate at least part of production, even in low-volume, high-mix applications. The key to getting started is to find the simplest solution that suits your requirements. Working with an automation partner who understands your needs can help.

Machining centers offer a wide range of operations, but this adaptability comes with the need to maintain flexibility and always perform measurements successfully.

Machining is complementary to additive manufacturing and is a means of finishing metal 3D printed parts. The growing popularity of additive manufacturing in production means that there is an increased demand for post-processing, especially for machining.

Machining long titanium tufted needle rods requires a milling machine with a very long X-axis stroke. But the real challenge is heat compensation in Georgia's high temperatures.

The dual-spindle VMC improves output when space and other factors are limited. With W-axis compensation for the z-height difference, the setup doesn't have to be perfect to use two spindles simultaneously.

Among the characteristics such as structure and spindle quality, the following are several factors to consider when purchasing a vertical machining center.