The injection molding manufacturing process has completely changed the production of various products in different industries.

We are adding a new division Plastic injection molding, a manufacturing process that has revolutionized the production of a wide range of products in different industries. From the automotive and medical industries to electronics and consumer goods, injection molding has become a popular method for manufacturing high quality and cost-effective products to solve customer problems.

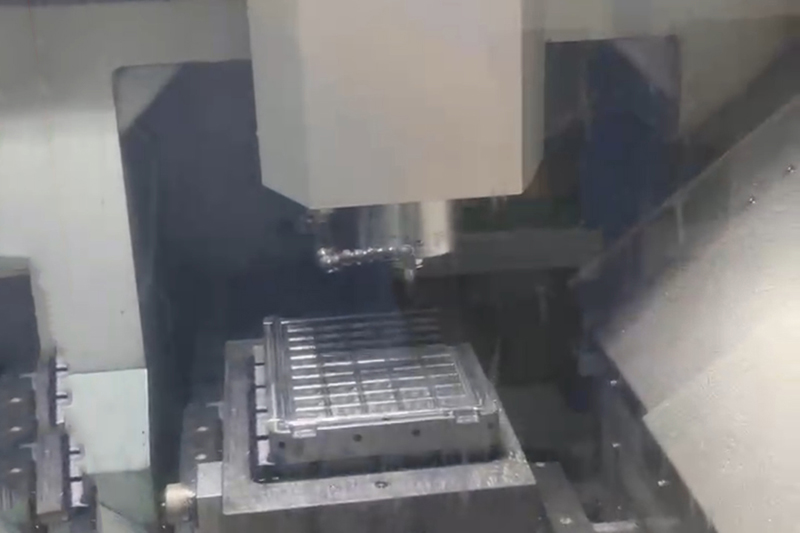

Injection molding involves melting a polymer material, usually in the form of particles, which are then injected into a mold cavity. The molten material takes the shape of a mold, and after cooling and solidification, the finished product pops out of the mold. The process allows the mass production of identical parts with high precision and efficiency.

Injection molding technology has made some progress. One major development is the use of 3D printing in injection moulds. This innovative technology allows for the creation of complex and customized mold designs, thereby improving product quality and reducing production time. In addition, 3D printed molds are more cost-effective compared to traditional molds, making them a popular choice for manufacturers.

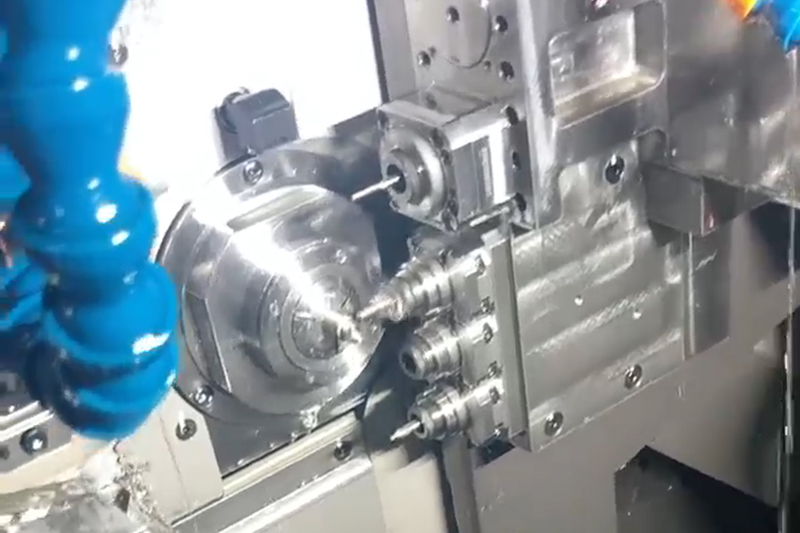

Automation has also changed the injection molding industry. Through the integration of robotics and artificial intelligence, manufacturers can now automate all stages of the injection molding process, from material handling to part removal and inspection. This not only increases productivity, but also ensures quality control throughout the production line.

One industry that benefits greatly from injection molding is the automotive, medical, electronics and other industries. Injection molded parts are widely used in vehicles due to their durability, accuracy and cost effectiveness. From interior components like dashboards and door handles to exterior components like bumpers and grilles, injection molding has revolutionized the way cars are made. In addition, advances in materials such as lightweight composites have made injection-molded parts more popular as automakers strive to reduce vehicle weight.